ANSI tile installation standards provide guidelines for materials, methods, and compliance, ensuring durability and aesthetics in tile projects. The ANSI A108, A118, and A136 standards offer comprehensive specifications for installers and manufacturers, covering substrates, adhesives, grouts, and safety protocols to achieve professional results.

Overview of ANSI A108, A118, and A136 Standards

ANSI A108, A118, and A136 standards outline requirements for ceramic and porcelain tile installations. A108 covers general installation practices, while A118 focuses on thin-set mortar specifications. A136 addresses grout performance criteria. Together, these standards ensure proper substrate preparation, material selection, and installation techniques, promoting durability, safety, and aesthetic appeal in tile projects. They are essential for contractors, architects, and manufacturers to achieve compliance and high-quality results.

Importance of Compliance with ANSI Standards

Compliance with ANSI tile installation standards ensures adherence to tested methods, reducing waste and speeding up operations. These standards promote professional results by specifying best practices for materials and techniques. By following A108, A118, and A136 guidelines, installers ensure durability, safety, and aesthetic appeal. Compliance also verifies that installations meet industry benchmarks, critical for both residential and commercial projects, and guarantees long-term performance and satisfaction.

Key Features of the ANSI Tile Installation Standards PDF

The ANSI Tile Installation Standards PDF provides comprehensive guidelines for ceramic, porcelain, and glass tile installations. It includes detailed specifications for materials, substrates, and methods, ensuring compliance with industry best practices. The document covers testing standards, installation techniques, and safety protocols. Specific sections address thin-set mortars, grout applications, and substrate preparation. It serves as a consolidated resource for professionals, offering clear, actionable recommendations to achieve durable, high-quality tile installations while adhering to ANSI A108, A118, and A136 standards.

General Requirements for Tile Installation

Ensuring substrates are properly prepared, using approved adhesives, and following environmental and safety guidelines are critical for successful tile installations.

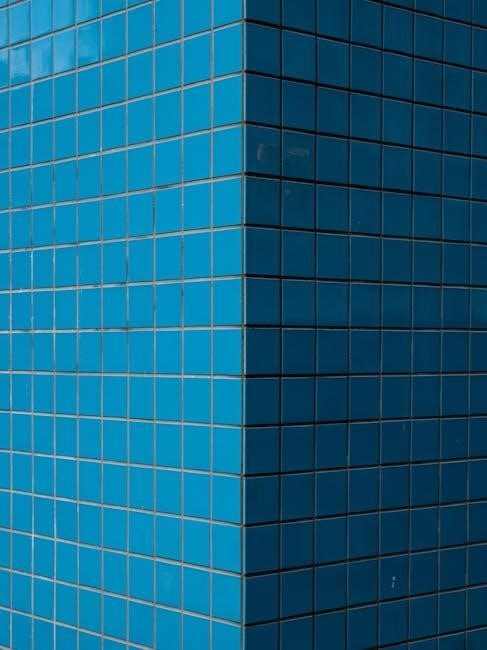

Structures and Substrates Preparation

Proper preparation of structures and substrates is essential for a durable tile installation. Substrates must be tested for moisture, structural integrity, and compatibility with adhesives. Cleaning and leveling surfaces ensure a stable base. ANSI standards emphasize the importance of substrate preparation to prevent failures. Non-compliant substrates can lead to tile detachment or uneven surfaces. Adherence to specified substrate requirements ensures long-lasting, professional results.

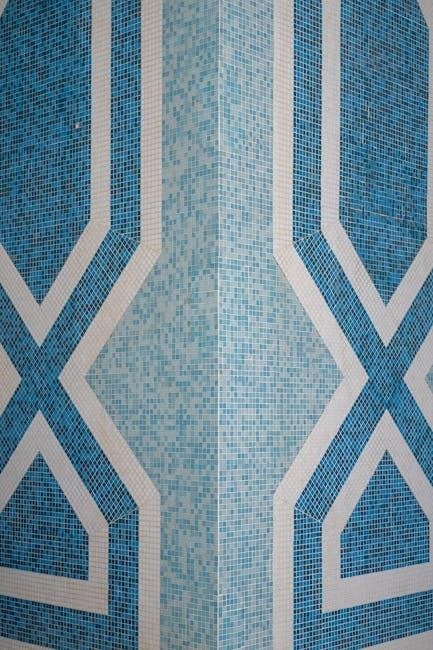

Tile Selection and Placement Guidelines

Tile selection and placement must align with ANSI standards to ensure optimal performance and aesthetics. Factors like tile type, size, and suitability for the intended use are critical. Proper placement involves aligning tiles accurately, maintaining consistent spacing, and ensuring patterns meet design requirements. Adherence to these guidelines guarantees durability, prevents issues, and enhances the overall appearance of the installation, meeting both functional and aesthetic goals as outlined in the ANSI tile installation standards PDF.

Environmental and Safety Considerations

Environmental and safety considerations are crucial in tile installation, as outlined in ANSI standards. Proper ventilation and use of protective equipment are essential to minimize exposure to harmful substances. Sustainable practices, such as reducing waste and using eco-friendly materials, align with environmental guidelines. Compliance ensures a safer workplace and adherence to regulations, promoting a healthier environment for both installers and occupants while meeting industry standards for responsible tile installation practices.

Specific ANSI Standards for Tile Installation

ANSI standards A108.01, A108.02, and A108.10 provide detailed requirements for tile installation, focusing on materials, methods, and specifications to ensure quality and durability in tile projects.

A108.01: General Requirements for Tile Installation

ANSI A108.01 outlines essential guidelines for tile installation, including substrate preparation, material selection, and installation methods. It ensures proper bonding, alignment, and durability, addressing both floor and wall applications. Compliance with A108.01 guarantees a stable and long-lasting installation, adhering to industry standards for quality and safety. This standard serves as a foundation for all tile projects, ensuring consistency and reliability in every detail;

A108.02: Specific Requirements for Thin-Set Mortars

ANSI A108.02 focuses on thin-set mortar specifications, detailing material requirements, mixing procedures, and application methods. It ensures proper bond strength and durability, addressing factors like substrate preparation and environmental conditions. The standard includes testing protocols for mortar performance and sets guidelines for optimal installation conditions, such as temperature and humidity. Compliance with A108.02 guarantees reliable and long-lasting tile installations, meeting industry standards for quality and performance in various tile applications.

A108.10: Latex Portland Cement Grout Specifications

ANSI A108.10 outlines specifications for latex Portland cement grout, detailing material requirements, mixing procedures, and application guidelines. It covers grout types, consistency, and curing times, ensuring proper fill and durability of tile joints. The standard addresses factors like grout cleanup, joint width, and environmental conditions, providing clear instructions for achieving optimal results. Compliance with A108.10 ensures long-lasting, visually appealing tile installations with minimal shrinkage and enhanced performance.

Materials and Substrates for Tile Installation

ANSI standards specify materials like ceramic, porcelain, glass, and natural stone tiles, as well as substrates such as concrete, plywood, and drywall, ensuring compatibility and durability.

Types of Adhesives and Their Applications

ANSI standards detail various adhesives for tile installation, including cement-based thin-set mortars, latex-modified adhesives, and epoxy-based systems. Each type suits specific conditions, such as moisture exposure or heavy traffic. Thin-set mortars are ideal for most ceramic and porcelain tiles, while epoxy adhesives provide superior strength for large-format or high-stress applications. Proper adhesive selection ensures bonding durability and prevents failures, aligning with A108 and A118 standards for optimal results.

Grout Selection and Application Standards

ANSI standards specify grout types and application methods. Latex Portland cement grout (A108.10) is suitable for most ceramic and porcelain tiles, while epoxy grout (A118.3) is recommended for high-stress areas. Proper mixing, application, and cleaning ensure optimal performance. Grout must be applied evenly, with joints cleaned before curing. Compliance with these standards ensures durability and prevents issues like cracking or staining, aligning with industry best practices for professional tile installations.

Substrate Preparation and Inspection

Proper substrate preparation is critical for successful tile installation. ANSI standards require substrates to be structurally sound, clean, and free of contaminants. Floors must be level, with deviations not exceeding 1/4 inch in 10 feet. Cracks and unevenness must be addressed before tile placement. Inspection ensures surfaces meet specifications, preventing future issues. Compliance with A108.01 guidelines guarantees a stable base, essential for durable and long-lasting tile installations that meet industry standards and aesthetic expectations;

Installation Methods and Techniques

ANSI installation standards outline methods and techniques for tile placement, emphasizing adherence to A108 and A118 guidelines. Proper substrate preparation and material selection ensure durability and aesthetic appeal.

Wet-Set Method for Ceramic Tile Installation

The Wet-Set Method, outlined in ANSI A108.1A, involves embedding tiles in a mortar bed, ensuring strong adhesion and durability. This traditional technique requires a prepared substrate, precise mortar application, and proper tile placement. It is ideal for large-scale projects and heavy-use areas, as it provides exceptional stability. Compliance with ANSI standards ensures long-lasting results, making it a preferred choice for professional installers seeking reliability and aesthetic consistency in ceramic tile installations.

Thin-Set Method for Porcelain and Glass Tile

The Thin-Set Method, detailed in ANSI A108.02, uses a thin layer of adhesive mortar for installing porcelain and glass tiles. This technique offers superior adhesion and flexibility, making it ideal for delicate tiles. Proper surface preparation is crucial, ensuring the substrate is clean, dry, and free of old adhesives. This method provides a uniform finish and minimizes tile movement, making it a preferred choice for modern installations due to its ease of use and enhanced durability.

Specialized Installation Techniques for Large Format Tiles

Large format tiles require specialized techniques to ensure stability and aesthetics. Proper substrate preparation is critical, with surfaces needing to be level, plumb, and free of defects. Alignment tools, such as laser guides, are essential for precise placement. Adhesives must be applied with the correct notch trowel to achieve full coverage. Handling large tiles demands care to prevent breakage, often requiring two-person teams. These methods minimize lippage and ensure a professional finish, adhering to ANSI standards for durability and visual appeal.

Preparation and Layout

Surface inspection ensures substrates are level and plumb, while layout planning involves measuring and marking for accurate tile placement, promoting efficiency and visual appeal.

Surface Inspection and Correction

Surface inspection ensures substrates are level, plumb, and clean, free from cracks or contamination; Correction involves patching uneven areas with appropriate compounds and sanding to achieve a smooth, stable base for tile installation. Proper preparation prevents future issues like uneven tiles or grout cracks, ensuring a durable and visually appealing result. All corrections must cure as per manufacturer instructions before proceeding with tile placement.

Layout Planning and Execution

Layout planning involves determining the starting point, ensuring symmetry, and marking grid lines using chalk or laser levels. Proper execution requires aligning tiles with walls and obstructions, adjusting for cuts, and maintaining consistent spacing. This step ensures a balanced and visually appealing installation, adhering to ANSI standards for professional results and long-lasting durability.

Alignment and Spacing Requirements

Alignment and spacing must adhere to ANSI standards to ensure professional and durable installations. Grout joints should typically range from 1/8 inch to 1/2 inch, depending on tile type and location. Tiles must align with walls, surfaces, and patterns, maintaining consistency. Proper spacing prevents unevenness and ensures structural integrity. Laser levels and chalk lines aid in precise alignment. Minimizing cuts and planning layouts to fit the space are critical for a polished finish, adhering to ANSI guidelines for both aesthetics and functionality.

Tools and Equipment for Tile Installation

Essential tools include tile cutters, notched trowels, levels, and grout floats. Proper equipment ensures precise cuts, even adhesion, and smooth grouting, meeting ANSI standards for quality installations.

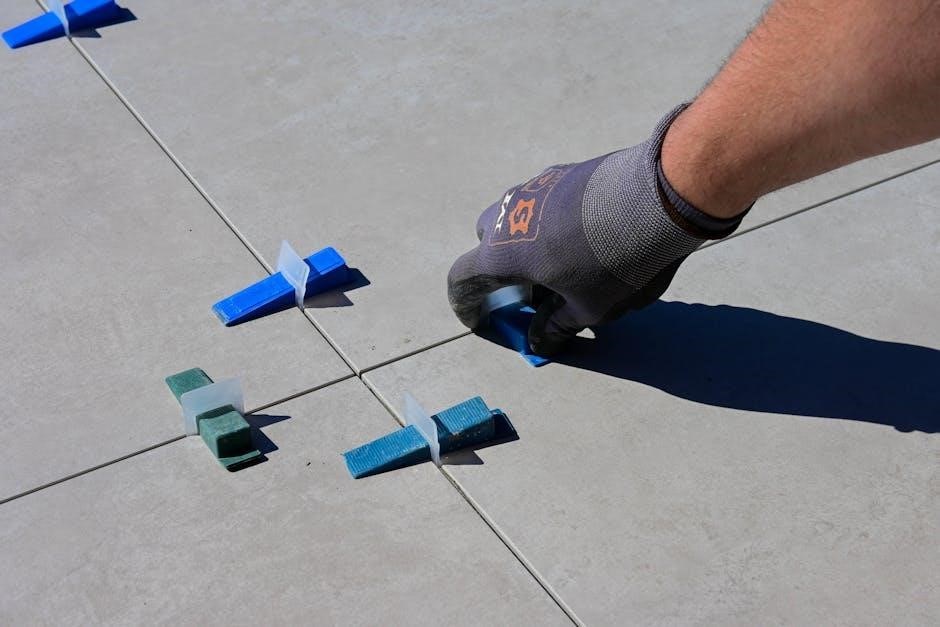

Essential Tools for Professional Installation

Professional tile installation requires specific tools for precision and efficiency. Essential tools include a notched trowel for applying adhesive, a tile cutter or wet saw for precise cuts, a level to ensure even placement, and a grout float for smooth finishes. Additionally, spacers maintain consistent gaps, while a rubber mallet taps tiles into place. These tools, adhering to ANSI standards, ensure durability, alignment, and a high-quality finish, making them indispensable for successful tile installations.

Equipment for Cutting, Grinding, and Polishing

Professional tile installation requires specialized equipment for cutting, grinding, and polishing. A wet saw is essential for precise cuts, while an angle grinder with diamond blades handles intricate shapes and edge work. Polishing machines with progressively finer pads achieve high-gloss finishes. Diamond-coated drill bits and routers also aid in creating holes or curved cuts. These tools ensure tiles meet ANSI standards for fit, finish, and durability, while maintaining safety and efficiency during installation processes.

Measurement and Alignment Tools

Accurate measurement and alignment are critical for successful tile installation. Essential tools include laser levels for ensuring even surfaces, tape measures for precise cuts, and spirit levels to verify plumb and level alignments. Pencil markers are used for layout markings, while digital measuring devices enhance precision. These tools ensure compliance with ANSI standards, promoting safety, efficiency, and professional results in tile placement and overall project quality.

Grouting and Sealing

Grouting and sealing are vital for enhancing durability and aesthetics. ANSI standards specify materials like cement-based and epoxy grouts, ensuring proper application and curing times for optimal results.

Grouting Techniques and Materials

ANSI standards detail grouting techniques and materials, emphasizing proper application for durability. Cement-based grouts are common, while epoxy grouts offer superior chemical resistance. Latex Portland cement grout, specified in A108.10, is ideal for demanding environments. Grouting should be applied evenly, filling joints completely. Mixing and spreading techniques must align with manufacturer instructions to avoid uneven color or texture. Proper curing times are essential for strength and longevity, ensuring a professional finish that enhances both functionality and aesthetics in tile installations.

Sealing Requirements for Different Tile Types

ANSI standards outline specific sealing requirements for various tile types, ensuring protection and longevity. Ceramic and porcelain tiles may require water-based sealers, while natural stone demands oil-resistant treatments. Glass tiles often need specialized coatings to prevent etching. Test results and manufacturer recommendations guide sealer selection. Proper application methods and curing times are emphasized to maintain tile integrity and appearance, adhering to ANSI specifications for optimal performance and durability. Regular maintenance is also recommended to uphold sealing effectiveness.

Curing and Maintenance Recommendations

Proper curing and maintenance are crucial for extending tile longevity. ANSI standards recommend allowing grout to cure for 24-72 hours before sealing. Regular cleaning with pH-neutral cleaners prevents dirt buildup. For natural stone, periodic inspections ensure sealers remain effective. Ceramic and porcelain tiles benefit from gentle scrubbing to avoid abrasion. Following manufacturer guidelines for maintenance ensures compliance with ANSI standards, preserving both functionality and aesthetics while preventing premature wear and tear. Scheduled upkeep is essential for sustained durability and appearance retention.

Safety and Compliance

ANSI tile installation standards emphasize safety and compliance, ensuring adherence to industry protocols that protect installers, buildings, and occupants while maintaining high-quality tile installations and durability.

Occupational Safety Guidelines for Installers

ANSI standards emphasize safety protocols for tile installers, including the use of personal protective equipment, proper handling of materials, and adherence to hazard communication guidelines. Installers must follow manufacturer instructions for adhesives and grouts, ensuring safe working conditions. Regular training on safety practices and compliance with local regulations are essential to prevent accidents and maintain a secure environment during tile installation projects.

Compliance with Local Building Codes

Adherence to local building codes is crucial for ensuring tile installations meet regional safety and structural requirements. While ANSI standards provide foundational guidelines, local codes may add specific provisions. Compliance ensures installations are durable, safe, and meet community standards. Installers must verify local regulations and incorporate them into their practices to avoid non-compliance issues. Proper documentation and inspections further validate adherence to both ANSI standards and local building codes, ensuring successful project execution and long-term performance.

Quality Control and Inspection Processes

Adherence to ANSI standards ensures quality control in tile installation. Rigorous inspection processes, including pre-installation checks and materials verification, guarantee compliance. Workmanship must align with specified guidelines, and installation methods should follow approved techniques. Proper documentation and compliance verification are essential for maintaining high standards. These practices minimize defects, enhance durability, and ensure installations meet both ANSI and local requirements, providing a reliable framework for successful tile projects.

ANSI tile installation standards provide a comprehensive guide, ensuring durability and aesthetic appeal. Adherence to these guidelines guarantees professional results and long-lasting tile projects.

Best Practices for Successful Tile Installation

Adhering to ANSI tile installation standards ensures professional results. Proper substrate preparation, accurate material selection, and precise surface inspection are essential. Follow A108.01 for general requirements and A108.02 for thin-set mortars. Use A118 standards for adhesives and ensure alignment and spacing meet specified guidelines. Apply grouting techniques as outlined in A108.10 for latex Portland cement grout. Regularly inspect work and address issues promptly to achieve a durable, aesthetically pleasing finish. Minimize waste by planning layouts carefully, ensuring compliance with safety and quality standards.

Future Trends in Tile Installation Standards

Future trends in ANSI tile installation standards will focus on sustainability, advanced materials, and digital integration. Expect expanded specifications for large-format tiles, gauged porcelain slabs, and eco-friendly adhesives. Standards will likely incorporate new testing methods for durability and environmental impact. Digital tools for layout planning and quality control will become more prevalent, enhancing precision and efficiency. Updates will also address emerging materials like glass and metallic tiles, ensuring installations meet modern design and performance demands while maintaining safety and compliance.